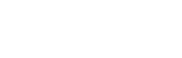

Our involvement in flow measurement is mainly around the evaluation of the performance of manufactured parts, checking the measured flow is of an acceptable level. This is generally performed on precision manufactured parts but has been applied in other areas such as high volume injection moulded components.

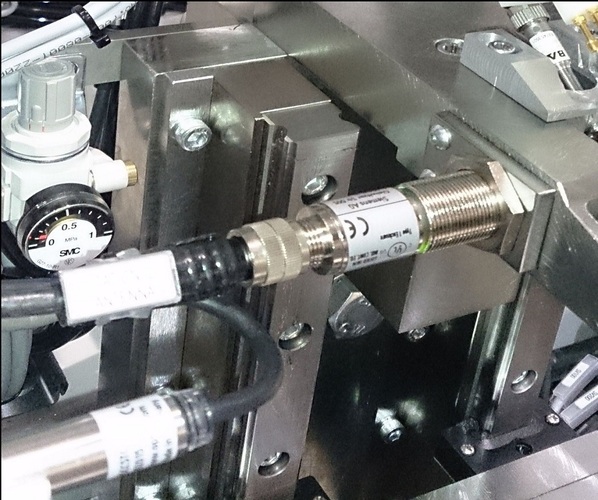

In order to achieve accurate flow measurement many factors must be considered. These include the temperature of the test medium, the temperature of the component, the pressure at which the test fluid is supplied, back pressure applied to the component the duration of the measurement etc. Another important factor is the selection of the flow measurement method and the flow measurement technology.

Over the many years CAT has been performing flow measurement we have gained a great deal of experience in what is required to get accurate and repeatable results. Testing of each product is different and understanding all of the above factors while keeping the test cycle time to a minimum is where CAT excel.

| flow range | 0.0003-1800 L/min |

| pressure range | 70 mbar-3000 bar |

| back pressure | up to 500 bar |

| temperature range | ambient to 150°c |

| viscosity range | 0.8 to 120 cSt |

| cycle times | as low as 0.8 seconds per part |

The measurement of flow is performed across a multitude of industries for many reasons from dosing control to component evaluation. Many different measurement technologies are available each with their own advantages.