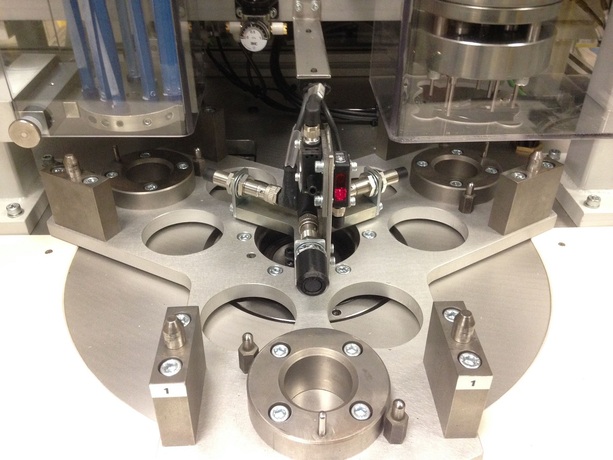

This bespoke system measures multiple aspects of 400-series diesel engines, including head gasket thickness and fuel injection pump shim thickness.

- High-Precision Technology: Features a Micro Epsilon 2060 measurement sensor mounted on a 6-axis robotic arm for accurate, automated measurement.

- Flexible Production: Handles any engine variant in any order — no tooling changes required.

- Data Integration: Results are stored in a local SQL server database and linked to the factory MES system for real-time traceability.

The system is designed for accuracy, efficiency, and reliability, helping manufacturers maintain strict quality standards