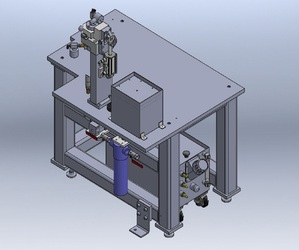

The CAT in-process wash module consists of four basic features and can be used for pre-operation gauging or post operation cleaning with all the hardware specified to achieve the customer’s requirements.

• power unit

• fixture

• drain dissipation tank

• electrical and software control enclosure

The power unit

Consists of the fluid reservoir complete with a pump motor set to deliver the fluid, a valve manifold to divert the fluid to wash or circulation and an inline filter for permanent filtration when the pump is running.

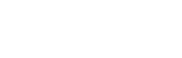

The fixture

This is a uniquely designed component enclosure which has a top access for auto-loading with ports for the wash fluid and the drying air.

The drain and dissipation tank

Comprises a small sealed tank filled with filter foam which allows the wash fluid to drain through back to the main power unit’s reservoir and also helps to eliminate foaming when the drying air is passed through.

The electrical and software control enclosure

Houses all the necessary hardware for operating and sequencing the wash and dry program. The host machine can be used to perform this function if preferred.