Precision Lapping & Deburring Machines

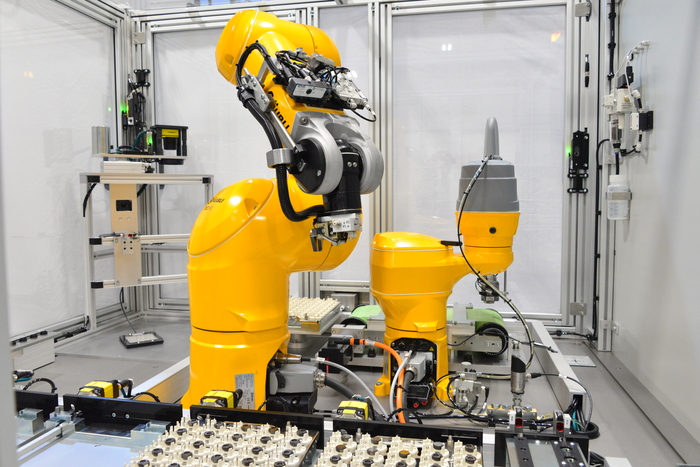

Curtis Assemble & Test Ltd (CAT) design and build precision lapping and deburring machines to meet the demanding requirements of the automotive and advanced manufacturing industries. Our automated systems remove micro burrs, improve surface finishes, and ensure every component meets strict quality standards.

Using robotic handling and advanced vision systems, our lapping and deburring solutions deliver consistent, repeatable results with full process monitoring and traceability.

How Our Systems Work

⚙️ Automated Part Handling – Components are picked from input pallets and inspected by a camera system to verify orientation and alignment. If required, the robot automatically flips the part before placing it on the lapping table.

⚙️ Precision Lapping Process – A second robot applies a controlled downward force and performs a figure-of-eight lapping motion. Multiple steps can be programmed to control lapping radius, speed, applied load, and the number of laps for precise, repeatable finishes.

⚙️ Quality Assurance – If a part fails inspection, the system uses a vacuum gripper to segregate defective components, ensuring they are stored separately from compliant parts.

Why Choose CAT Lapping & Deburring Solutions?

✔️ Automated, repeatable removal of micro burrs for consistent quality

✔️ Flexible programming for multiple lapping parameters

✔️ Integrated robotics and vision systems for orientation and accuracy

✔️ Proven expertise in delivering turnkey solutions for automotive and precision manufacturing industries

Our systems are tailored to meet customer-specific requirements, from stand-alone rigs to fully integrated automated production lines.