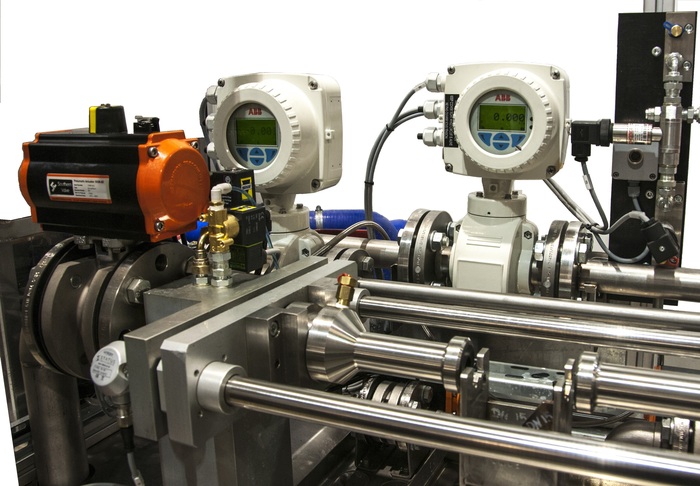

Subcontract Testing

When developing a new product, proving performance criteria can be challenging. How will it behave under pressure? What cycle times will ensure repeatable results? And once optimised, how do you meet pre-production requirements efficiently and reliably?

Subcontract testing with Curtis Assemble & Test Ltd provides the answers. Our facilities allow you to validate performance, optimise cycle times, and assess repeatability without the need to invest in new equipment.

Subcontract testing is also invaluable in remanufacturing — helping you determine which components still have a useful service life, saving money and reducing waste.

Testing Facilities & Capabilities

⚙️ Hydraulic pressure testing – up to 3000 bar, measurable from 0.01 cc/min up to 20 cc/sec and higher

⚙️ Back pressure testing – up to 500 bar

⚙️ Temperature range – ambient to 60°C

⚙️ Viscosity range – 0.8 to 120 cSt

⚙️ Pressure stability – better than ±0.1 bar for steady state conditions

⚙️ Flow rate – up to 100 L/min depending on pressure

⚙️ Temperature control – ±1°C depending on fluid

⚙️ Evaluation criteria – pressure change over time (pressure decay/rise), timed pressure drop, measured flow (flow measurement/mass flow), blob growth

⚙️ Measurement media – air, hydraulic oil (ambient to 150°C), calibration fluid, water

⚙️ Pneumatic pressure testing – up to 250 bar

⚙️ Flow range – 0–500 L/min at pressures up to 3000 bar and temperatures up to 150°C

⚙️ Leak detection – pressure increase or decrease over time

All testing services subject to final details, quantities, agreement and timescales.

With extensive subcontract testing facilities, Curtis Assemble & Test Ltd help manufacturers reduce development time, validate performance, and meet pre-production targets. Contact our team today to discuss how subcontract testing can support your next project.