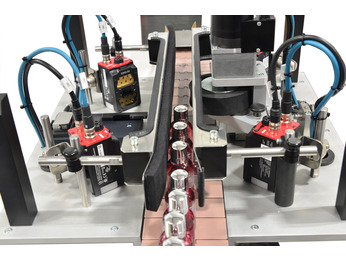

At Curtis Assemble & Test (CAT), we specialise in designing, manufacturing, and commissioning bespoke automated testing and assembly systems. Whether you need high-pressure hydraulic and pneumatic testing, vision inspection systems, or custom automation solutions, we deliver systems that are built to perform, designed to last, and tailored to your needs.

With a heritage dating back to 1973 through our origins in Douglas Curtis Machine Tools, CAT was founded in 1998 and continues to share its expertise with Curtis Machine Tools Ltd as part of the Douglas Curtis Machine Tools Group. With over 50 years of engineering excellence, we combine decades of experience with cutting-edge innovation to deliver turnkey solutions trusted by leading manufacturers worldwide.

FIND OUT MORE

FIND OUT MORE

FIND OUT MORE

FIND OUT MORE

- Turnkey provider — from initial design to full commissioning and support.

- Proven quality — trusted by leading manufacturers worldwide.

- 50 years of heritage — combining deep expertise with cutting-edge innovation.

- Bespoke engineering expertise — no “off-the-shelf” compromises.

- Problem-solving mindset — we often fix issues caused by cheaper, lower-quality alternatives.

- In-house expertise – design, build, and software all under one roof

Talk to our experts today and discover how CAT can deliver the bespoke automated testing and assembly solutionyour business needs.

- Hydraulic & Pneumatic Leak Testing - High-pressure testing up to 3000 bar (hydraulic) and 250 bar (pneumatic), with precision results and full data traceability.

- Subcontract Testing - Validate your components using our advanced in-house testing rigs for pressure, leakage, flow, and performance.

- Cleaning in Place (CIP) & High-Pressure Cleaning - Delivering precision component cleaning to meet the highest cleanliness standards.

- Vision Inspection Systems - Automated component inspection and code reading for quality control and regulatory compliance.

- Flow & Pressure Measurement - Measure flow ranges up to 500 l/min at pressures up to 3000 bar and temperatures up to 150°C.

- Automation & System Integration - From standalone rigs to fully integrated systems, we specialise in automation solutions tailored to your exact process needs.

- Repairing & Improving Existing Machines - We don’t just design from scratch — we can retrofit, upgrade, and improve existing systems to boost efficiency, reliability, and compliance.